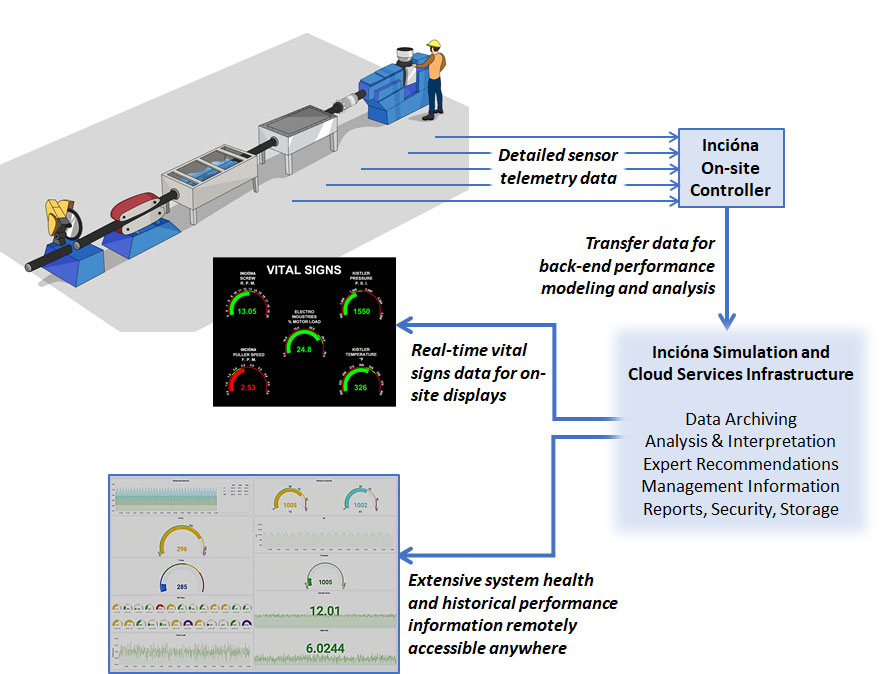

Incióna’s Expert Advisor monitors manufacturing operations, providing real-time feedback on process vitality as well as advisories for fine tuning process efficiency.

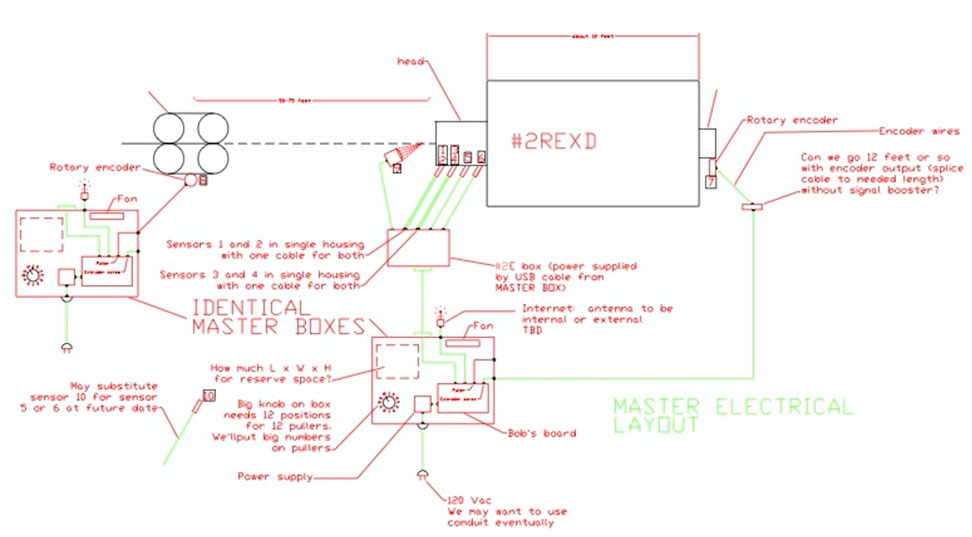

The system collects data from sensors monitoring critical operational parameters of the manufacturing process. The sensor data is continuously streamed to the cloud-based, customized System Behavior Model at the Incióna Service Center, where we process, analyze, evaluate and interpret the data.

The results are transmitted back to the production plant, where they are displayed in real-time on dedicated Incióna display screens, whether at the equipment operator’s station, a plant manager’s desk or at global corporate headquarters.

The Expert Advisor is not a fully-automated control system. Action decisions remain in the hands of the Operators, as informed by their practical experience and onsite knowledge.

Advisories are specific recommendations presented in language and visual cues extrusion operators will intuitively understand. These might include recommended process adjustments, troubleshooting advice or maintenance warnings.

Minimize manufacturing costs and down time.

Maximize product consistency, quality and throughput.

Give the operator continuous feedback on production line status.

Recommend actions for assuring optimal machine efficiency.

More customized data and advisories can also be sent to management and can be password protected if desired. Most displays are hierarchical, i.e., more granular information can be immediately accessed with the “More Info” link for additional in-depth technical or management level data, as well general information such as work order #, customer code, material being run, start time, planned run time, throughput, down time, machine efficiency rating, plant-wide efficiency with multiple installations., etc.

Incióna’s process modeling capability focuses on achieving an optimum cost/benefit to the user by combining what computers do best with what human operators do best. The Expert Advisor is not a restricted, fully-automated control system. Action decisions remain in the hands of the Operators, informed by their practical experience and onsite knowledge.

The Incióna Expert Advisor’s level of production augmentation takes a cue from the 80:20 rule of thumb. In contrast to the cost and complexity of full line automation, Incióna’s operator support approach can return about 80% of full automation benefits at about 20% of the cost.

Incióna’s Analytics-as-a-Service is the most cost-effective, customizable approach to being able to optimize production processes without the premium cost of full automation.

Incióna does all software upgrades and maintenance over the Internet. In an operation with multiple installations, upgrades are simultaneous and, therefore, always at the same version level.

Front end investment and installation costs are minimized in favor of a monthly service expense item.

The Incióna Vital Signs monitor continuously presents critical operational parameters in real time on dedicated display screens located at the production line. Back-end data displays provide extensive analytical information on overall system health and historical performance over time.